What Are Compound Dies?

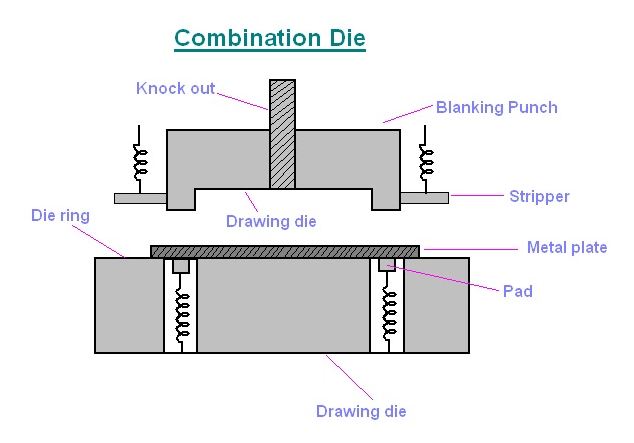

Compound dies are advanced tooling systems that perform multiple operations—typically blanking and piercing—in a single press stroke at the same die station. This results in superior dimensional accuracy, flatness, and clean part edges, making them ideal for disc-shaped, flat, or symmetric components requiring high repeatability.

Unlike progressive dies where the workpiece moves through multiple stations, compound dies perform all operations at a single station. This makes them exceptionally efficient for certain types of parts where dimensional relationships between features are critical.

Advantages of Compound Dies

Single-Stroke Multi-Operation

Performs two or more operations (e.g., blanking and piercing) in one press stroke, increasing efficiency and productivity.

High Dimensional Accuracy & Reduced Handling Time

Maintains close tolerances due to all operations occurring in a fixed alignment setup. Eliminates the need for intermediate part handling or repositioning between operations.

Faster Production Rates & Lower Die Maintenance

Shorter cycle times lead to higher output, ideal for mass production environments. Fewer moving components and synchronized actions result in longer tool life and easier upkeep.

Material Cost Savings

Optimized strip layout and precision cutting reduce scrap generation, leading to significant material cost savings in high-volume production.

Compact & Space-Saving

Combines multiple processes into a single die, saving floor space and simplifying press line layout for more efficient manufacturing operations.

Process Reliability & Better Flatness Control

Ensures consistent part quality with minimal variation across long production runs. Especially useful for producing flat parts where warping must be minimized.

Why Choose Compound Dies?

Compound dies are ideal for producing:

Disc-shaped, flat, or symmetric components requiring high repeatability and precision

Parts requiring superior dimensional accuracy between blanking and piercing operations

High-volume production runs where efficiency and material utilization are critical

Components with clean part edges and minimal flatness variation requirements

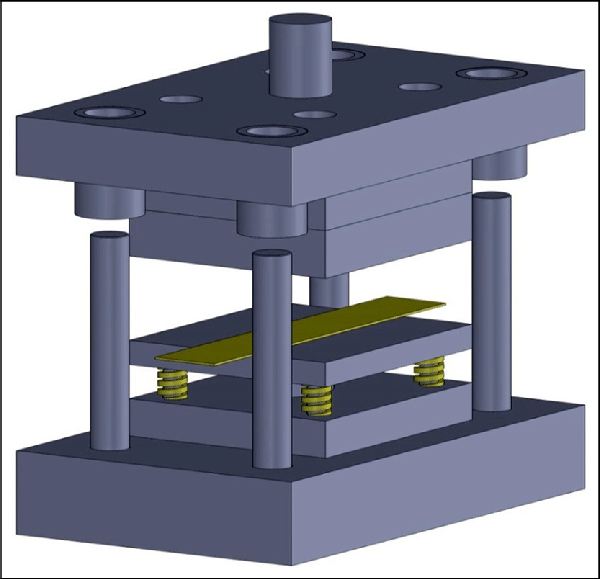

Key Features of Compound Dies

Simultaneous Operations

Multiple cutting and forming operations occur simultaneously at the same die station, ensuring perfect alignment.

Fixed Alignment Setup

All operations are performed with the workpiece in a fixed position, eliminating tolerance stack-up and positioning errors.

High-Force Capability

Designed to handle high cutting forces required for simultaneous blanking and piercing operations in a single stroke.

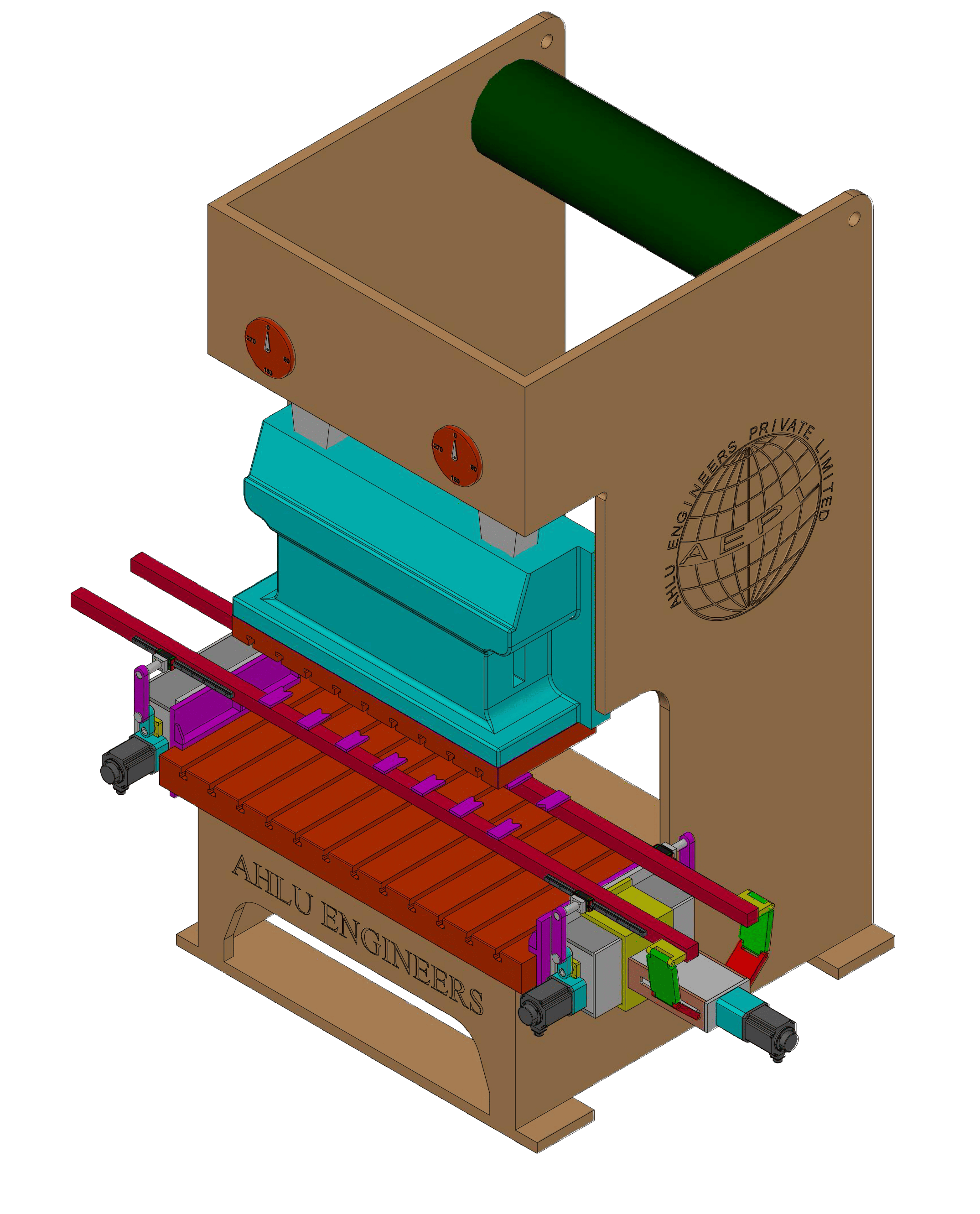

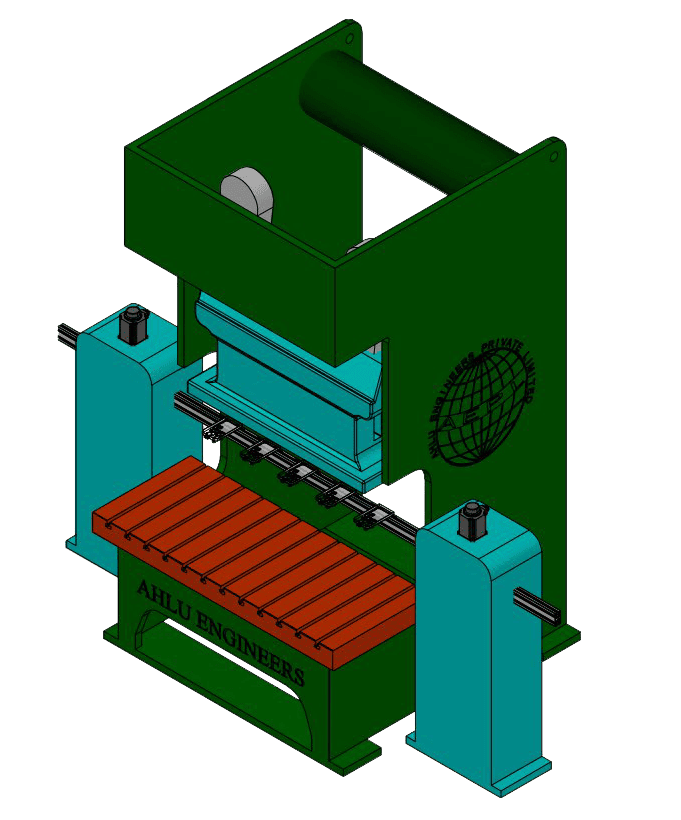

Easy Integration with Automation

Compound dies can be easily integrated with automated feeding and part removal systems for complete production automation.

Where Ahlu Engineers Adds Value

At Ahlu Engineers, we specialize in designing and building precision-engineered compound dies tailored to your specific applications. Our in-house expertise allows us to:

Optimize force distribution and cutting sequence for balanced die operation

Design precision alignment systems for consistent part quality

Engineer dies for maximum material utilization and minimal scrap generation

Provide comprehensive die validation and production optimization support

Industries We Serve

Electronics

(Connectors, Terminals, Circuit Components)

Medical Devices

(Precision Components, Surgical Instruments)

Hardware Manufacturing

(Washers, Fasteners, Hardware Elements)

Automotive

(Disc Components, Precision Parts)

Ready to Upscale Your Production with Precision?

At Ahlu Engineers, we don't just build tools — we engineer solutions that transform your manufacturing process into a high-precision, high-efficiency operation. Contact us today for custom compound die development, force optimization consultation, or complete precision tooling design services.

Explore Our Premium Solutions

Our wide array of expertly designed automation solutions, tailored to enhance your manufacturing processes with precision and efficiency.

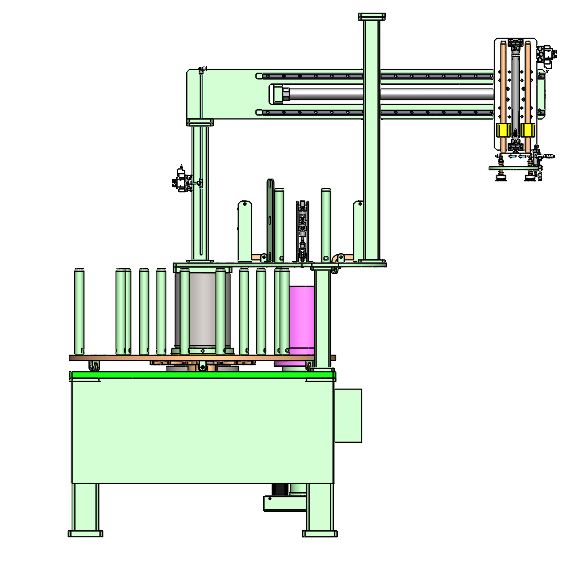

Ahlu Servo Transfer 3 Axis Double Bar type- AST3AII

Transfer Dies

Ahlu Servo Transfer 2 Axis Single Bar type- AST2AI

Indexing Stacker w/ Blank Feeder - AISBF Series

Need a Custom Automation Solution?

Our experienced engineers specialize in designing tailored automation systems that perfectly match your unique manufacturing requirements. From concept to implementation, we deliver precision-engineered solutions that boost productivity and efficiency.

✓Expert Engineering Team

45+ years of automation experience

✓Industry Leading Innovation

Cutting Edge automation solutions for modern challenges

✓Complete Support

From design to maintenance & training

Our automation experts are here to help.