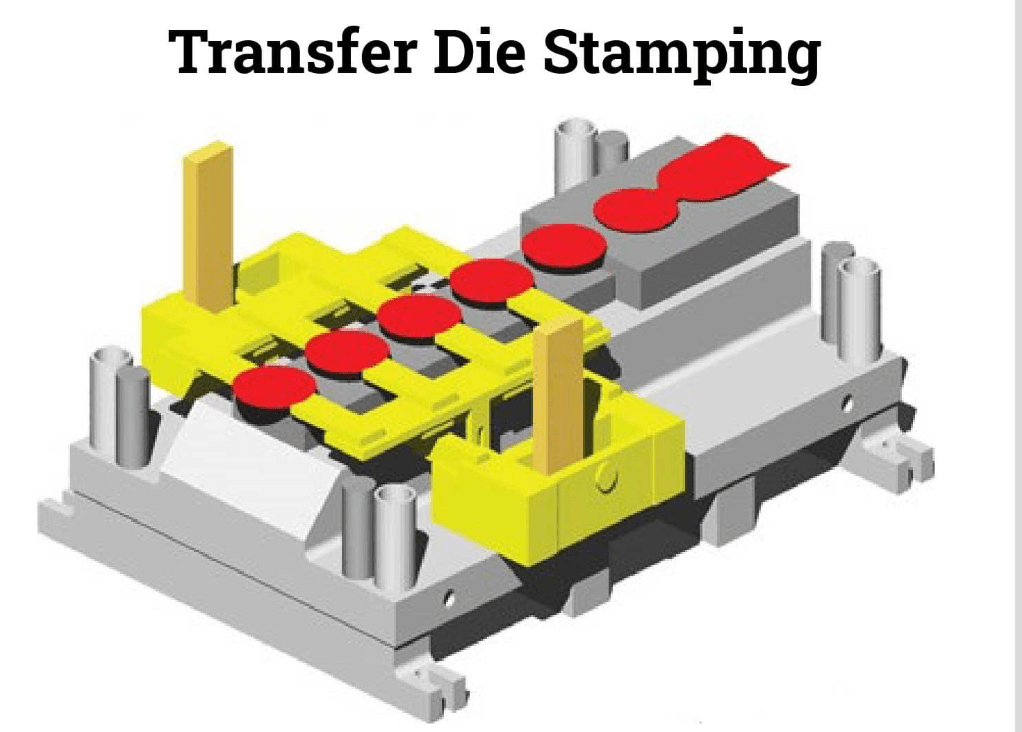

What Are Transfer Dies?

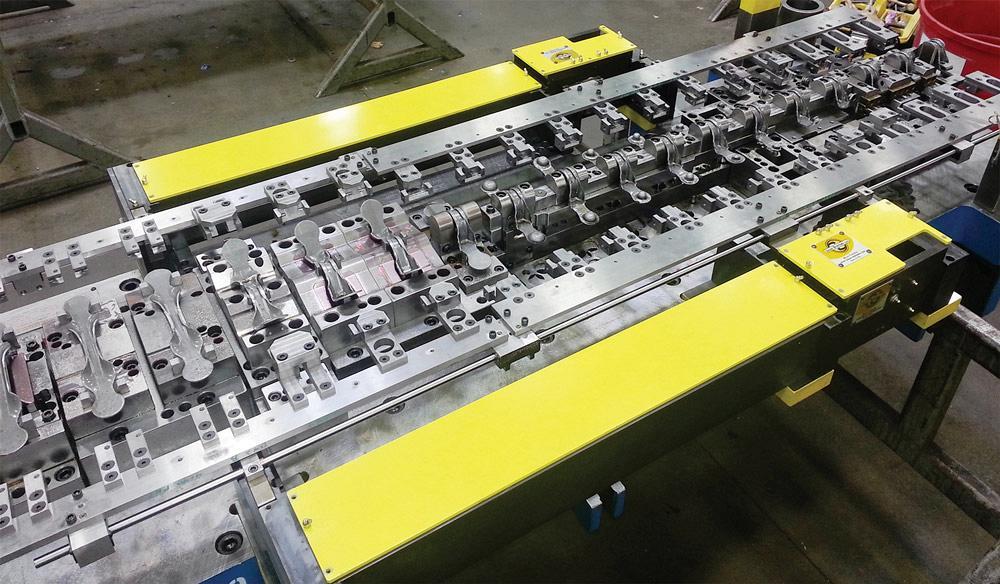

Transfer dies are a modern solution in the world of metal stamping, used predominantly in high-volume production environments. Unlike progressive dies that keep the workpiece attached to a carrier strip, transfer dies allow each part to move independently from one station to another within a single press. This process is ideal for manufacturing large, complex, or deep-drawn components.

Each die station is spaced at a consistent interval — known as the pitch — which defines how far a part must travel between forming operations. The entire system is synchronized within a single press stroke, enabling multiple forming stages in a streamlined cycle.

How Do Transfer Systems Work?

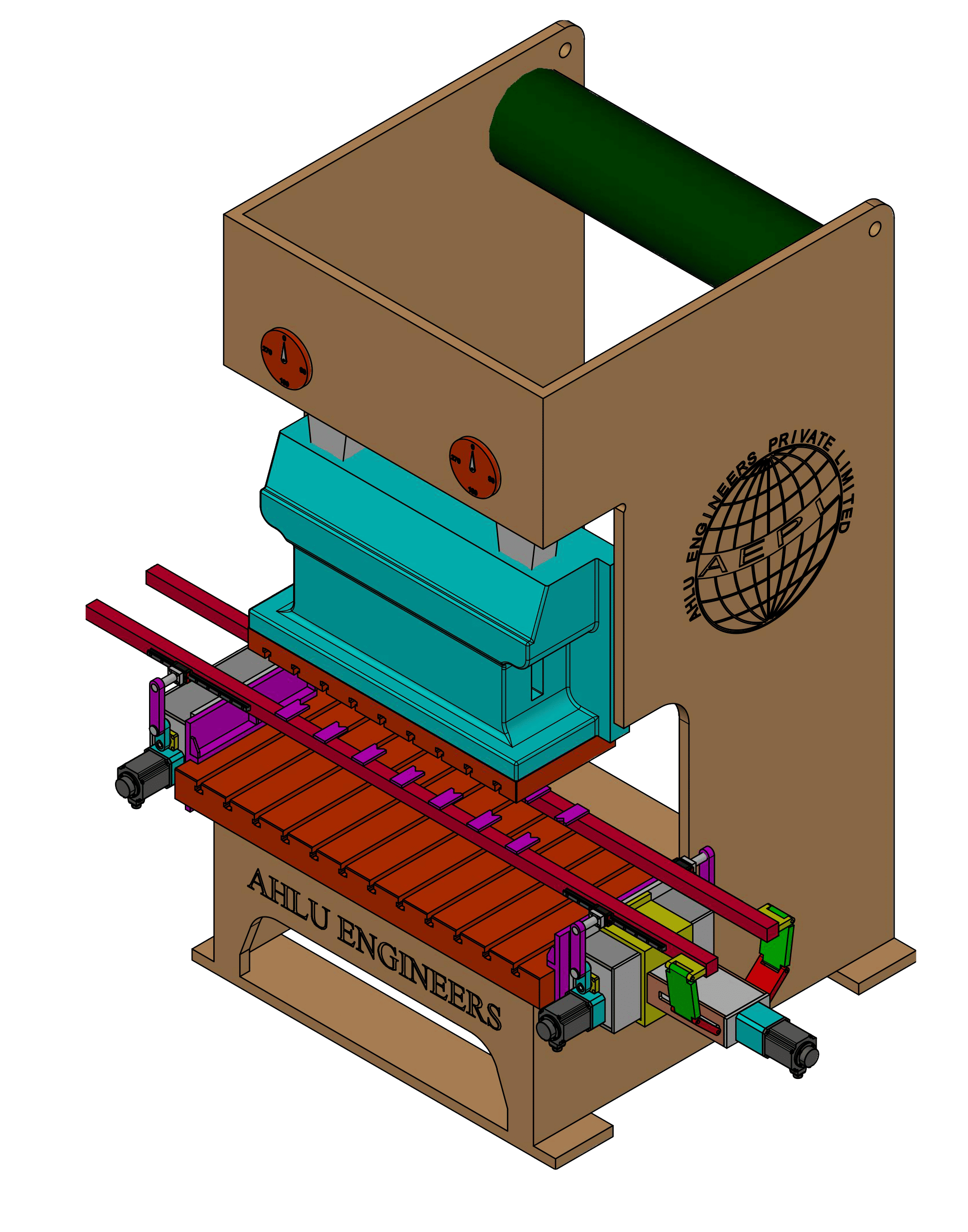

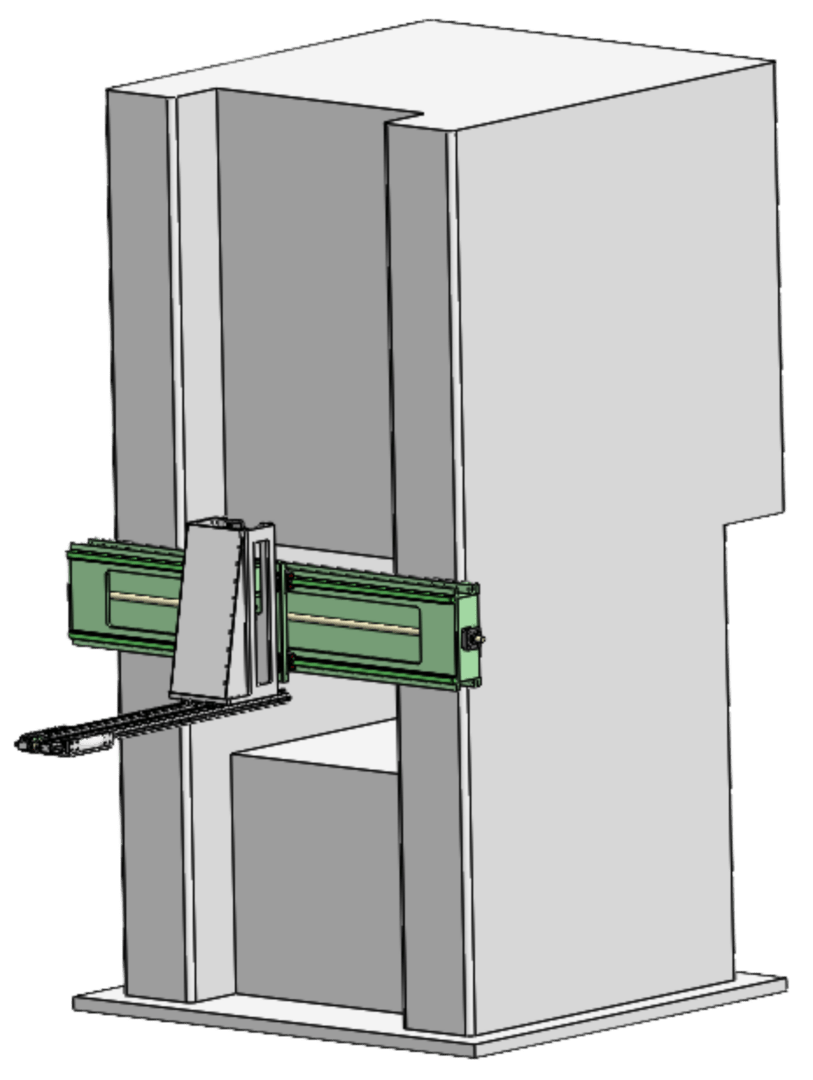

Instead of a traditional conveyor or hand-feeding, transfer systems use integrated mechanical rails positioned inside the press to pick and place parts. These transfer rails operate using two main configurations:

1

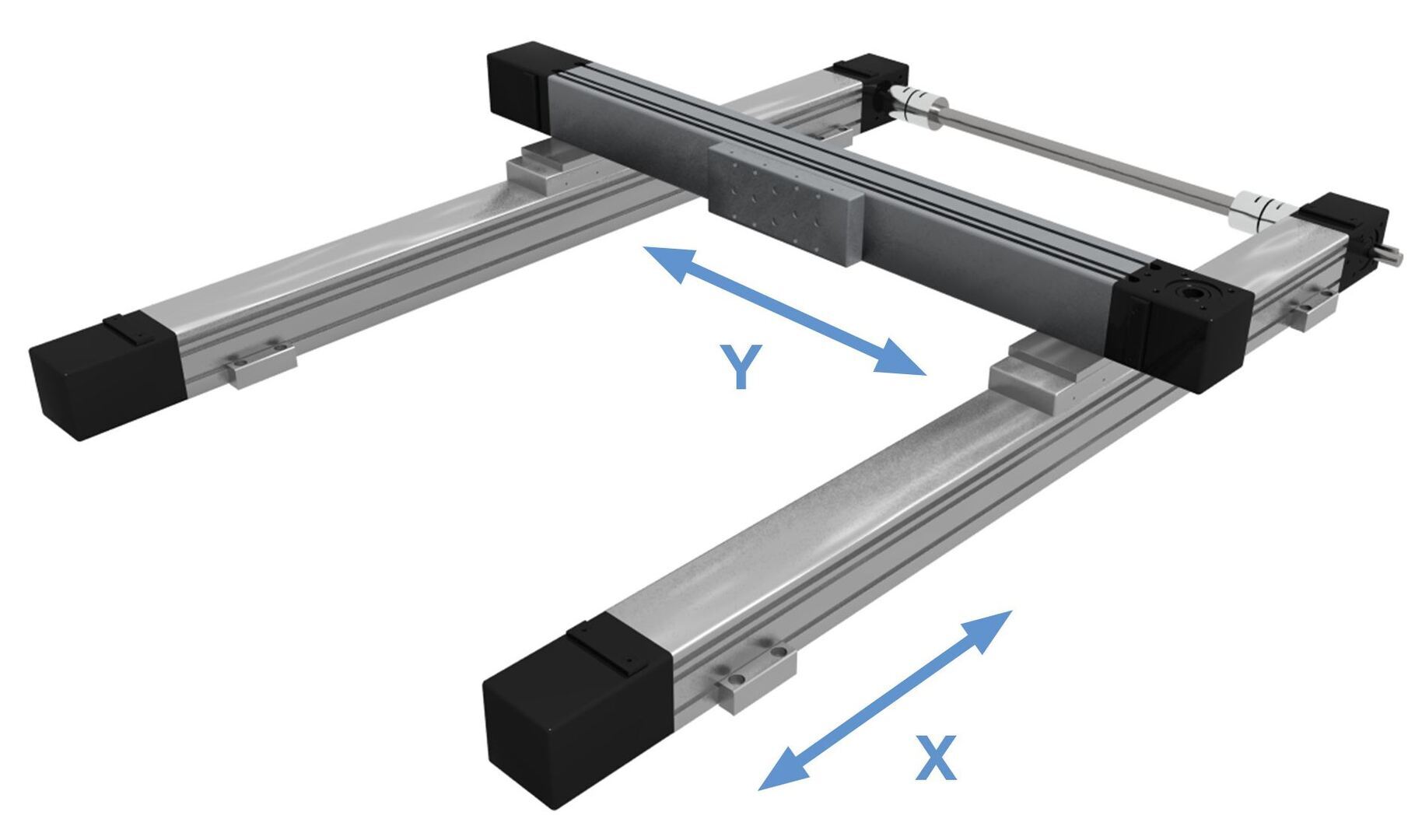

2-Axis Transfer Systems (X-Y Movement)

These rails grip the workpiece, move it forward to the next station, and release it — perfect for less complex parts.

2

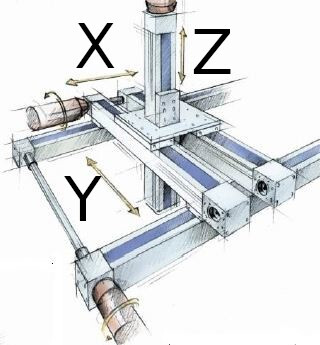

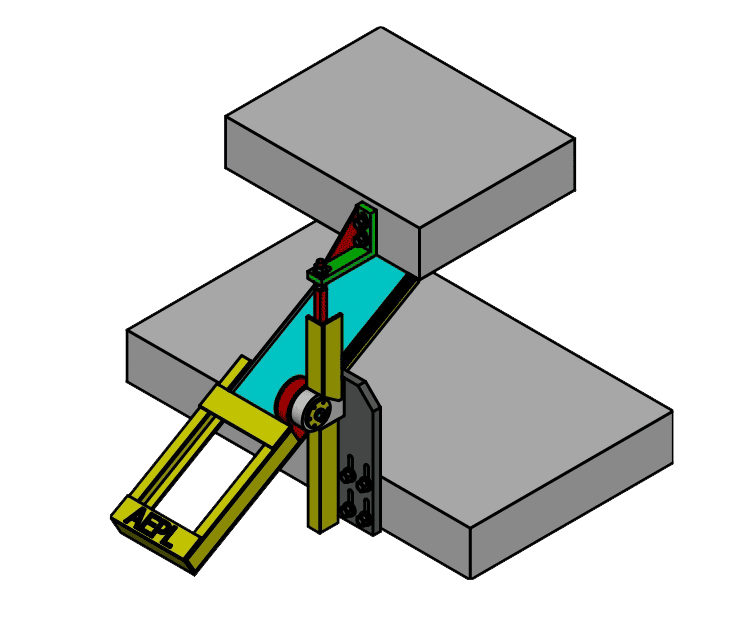

3-Axis Transfer Systems (X-Y-Z Movement)

In more advanced setups, rails not only move forward and grip the part, but also lift and lower it vertically, placing it precisely within the next die. This Z-axis motion ensures greater control, especially for deep-drawn or geometrically sensitive components.

Why Choose Transfer Dies?

Transfer dies are ideal for producing:

Axially symmetrical parts (e.g., automotive hubs, cookware, filters)

Large, deep-drawn components requiring multiple forming actions

Parts with features on multiple planes or requiring part orientation changes

Advantages of Transfer Die Systems

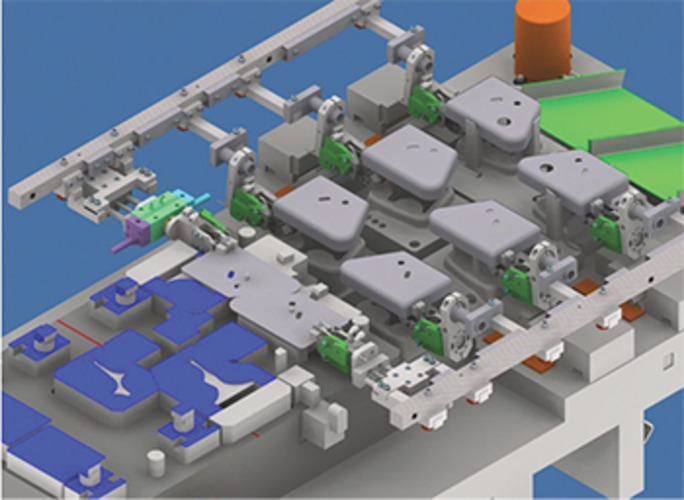

Versatility for Complex Parts

Transfer dies accommodate parts that need forming, drawing, trimming, piercing, and flanging — all within a single cycle.

Cost-Efficient Material Use

Since parts are not tethered to a strip, raw material can be cut into blanks in a way that reduces scrap, improving overall material utilization.

Speed Meets Size

Large-sized stampings can be moved efficiently between stations, even at high production speeds.

Programmable Servo Transfers

Modern transfer rails are driven by servo motors, allowing for precise synchronization with press speed, stroke length, and part geometry.

Part Reorientation Capability

The system allows in-cycle part flipping or rotation, essential for complex geometry components.

Where Ahlu Engineers Adds Value?

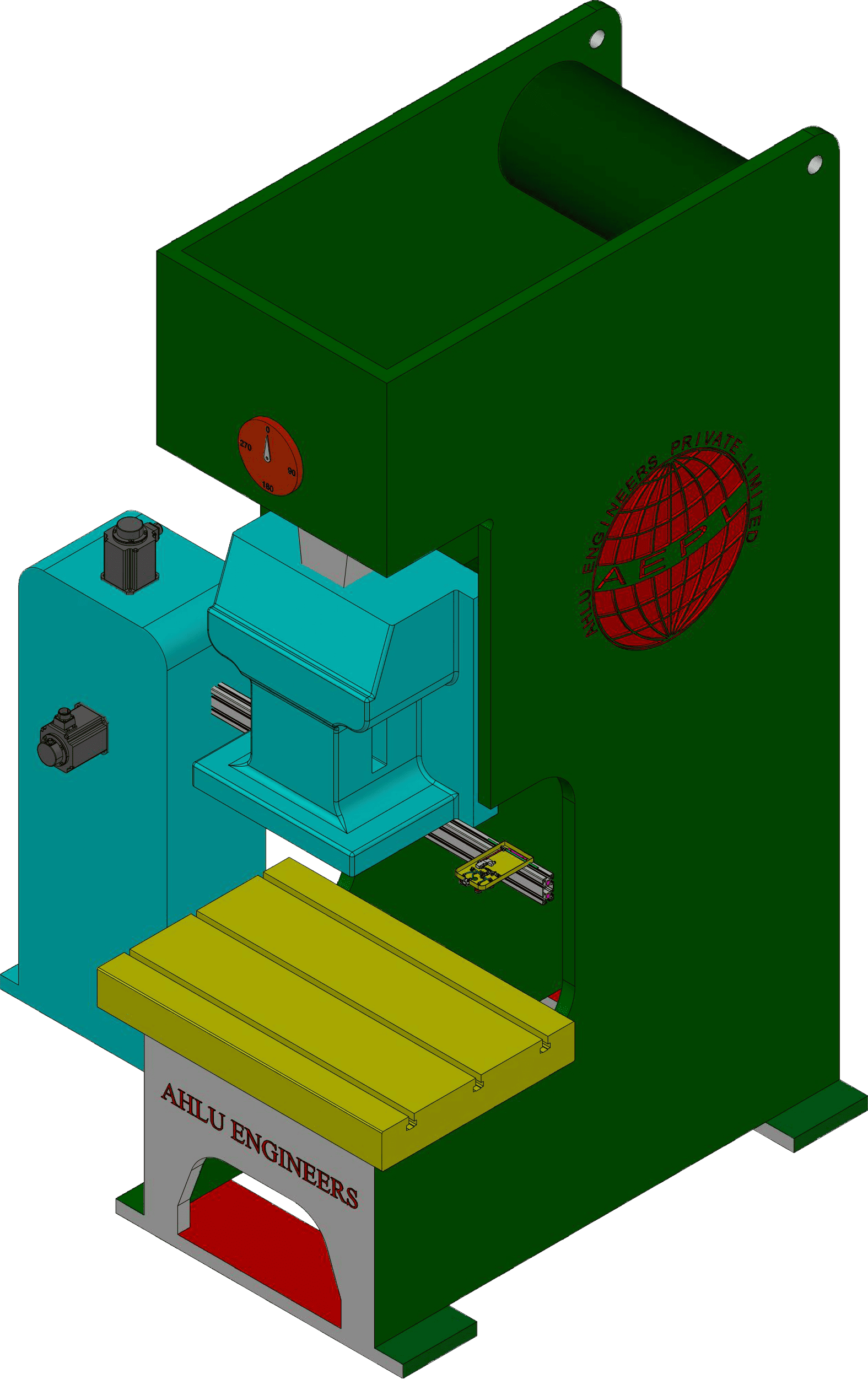

At Ahlu Engineers, we specialize in designing and building precision-engineered transfer dies tailored to your application. Our in-house expertise allows us to:

Customize die pitch and station layout for optimal throughput

Integrate servo-driven rail systems to enhance speed and flexibility

Engineer dies that handle complex, large, or deep-drawn parts with minimal operator intervention

Provide end-to-end die validation and try-out support

Industries We Serve

Automotive

(Chassis, Brackets, Suspension)

Consumer Appliances

(Cookware, Fan Covers)

Electrical Enclosures

Industrial Components

HVAC & Plumbing

Need Transfer Dies That Work Smarter?

At Ahlu Engineers, we don't just build tools — we engineer solutions that upgrade your production floor into a high-efficiency, low-waste environment. Contact us today for custom transfer die development, press automation consultation, or complete tool design services.

Explore Our Premium Solutions

Our wide array of expertly designed automation solutions, tailored to enhance your manufacturing processes with precision and efficiency.

Ahlu Cantilever Servo Transfer System- ACSTS Series

Ahlu Mechanical Press Flap Series- AMPF

Ahlu Servo Transfer 2 Axis Double Bar type- AST2AII

Ahlu Over Head Servo Transfer Robot - AOHST

Need a Custom Automation Solution?

Our experienced engineers specialize in designing tailored automation systems that perfectly match your unique manufacturing requirements. From concept to implementation, we deliver precision-engineered solutions that boost productivity and efficiency.

✓Expert Engineering Team

45+ years of automation experience

✓Industry Leading Innovation

Cutting Edge automation solutions for modern challenges

✓Complete Support

From design to maintenance & training

Our automation experts are here to help.