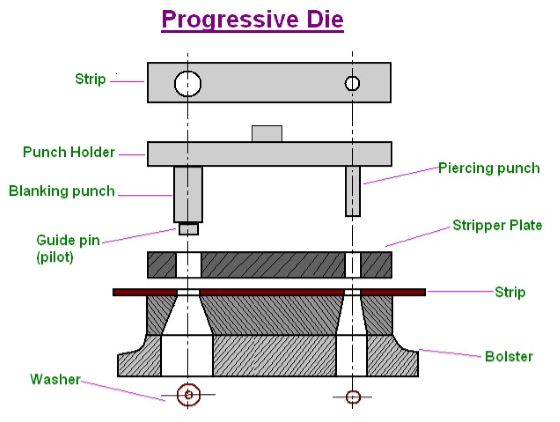

What Are Progressive Dies?

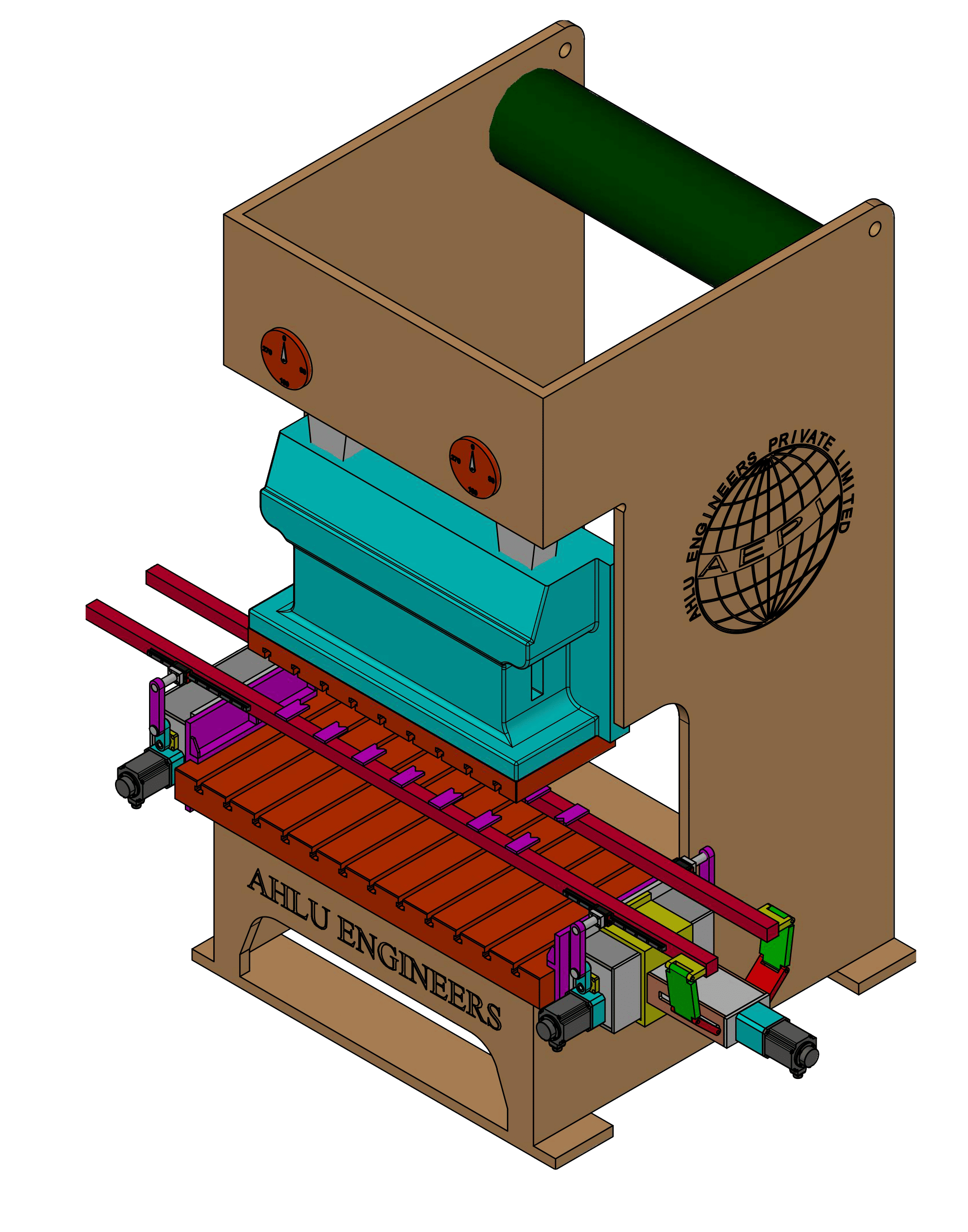

Progressive Dies is a fast and efficient way to make metal parts. In this process, a long strip of metal is fed from a coil into a tool called a progressive die. The metal moves through a series of stations inside the die. At each station, a different operation is performed-like cutting, bending, or shaping.

By the time the metal strip reaches the end, a finished part is produced, and the leftover strip is removed as scrap. This process enables cost-efficient manufacturing through sequential operations, all within a single press stroke.

Progressive Dies in Action

Watch how our progressive dies work in real-time manufacturing environments, demonstrating the precision and efficiency of our tooling solutions.

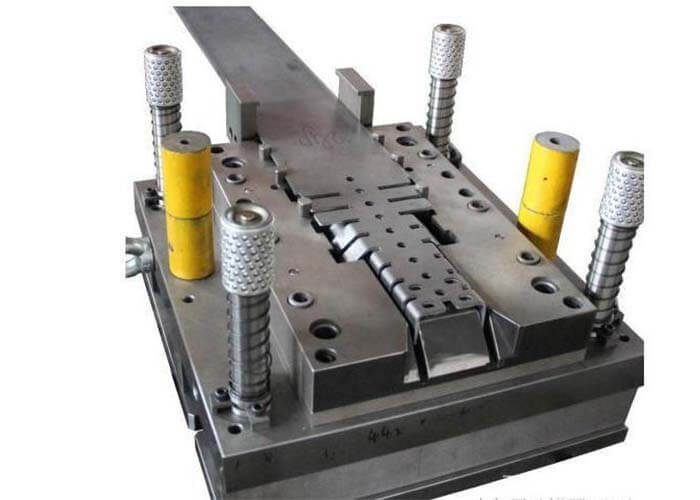

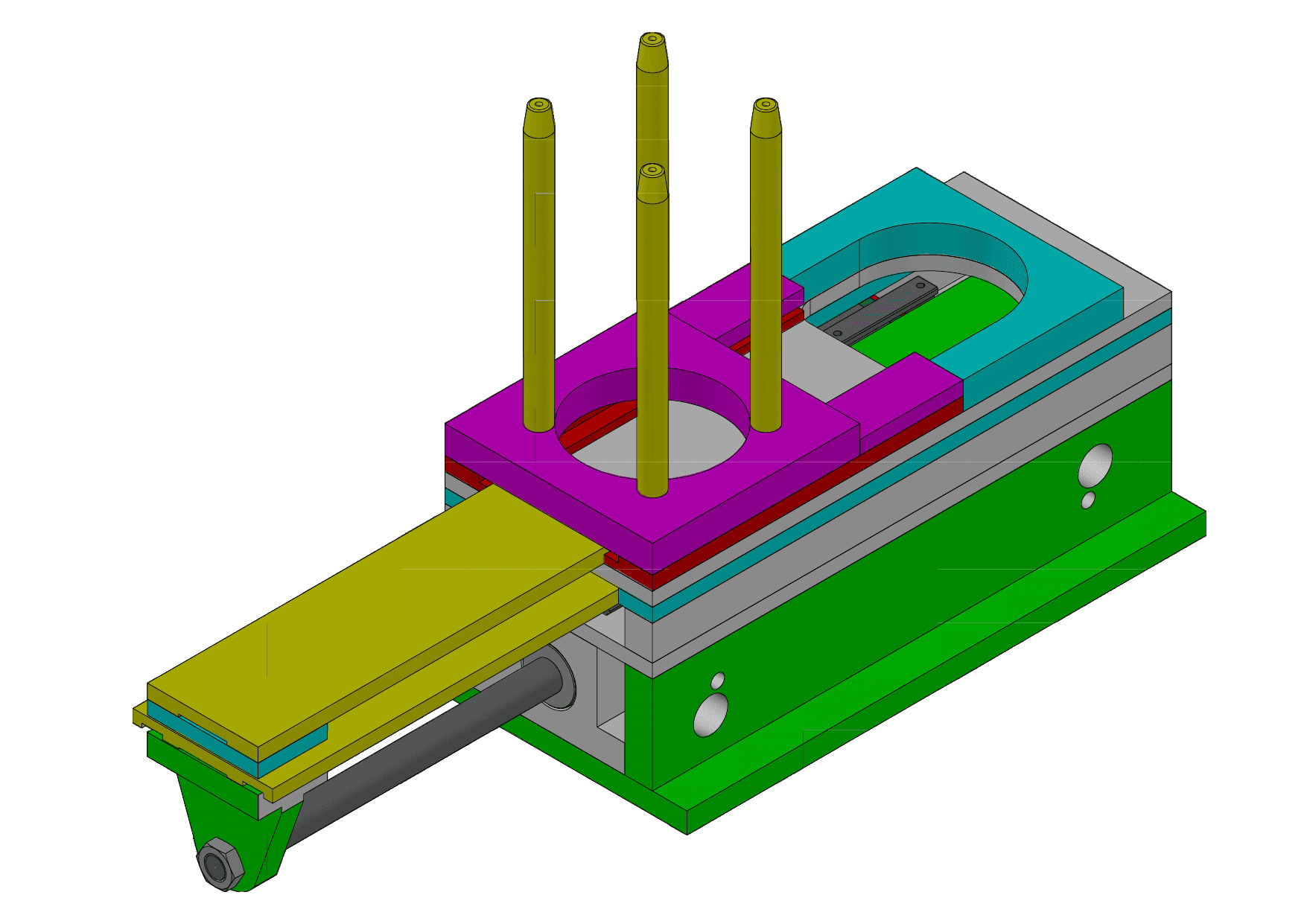

Types of Progressive Dies We Manufacture

We design and manufacture a wide variety of progressive dies tailored to diverse part geometries and production volumes:

1

Single-Row Progressive Dies

Ideal for medium to high-volume production with streamlined linear tooling.

2

Multi-Row Progressive Dies

Suited for producing multiple identical or mirrored components in one operation, doubling productivity.

3

Compound Progressive Dies

An integrated solution that combines cutting and forming within the same station—used where extreme precision and repeatability are required.

Why Choose Progressive Dies?

Progressive dies are ideal for producing:

High-volume production runs with consistent quality and minimal operator intervention

Complex multi-operation parts requiring cutting, bending, forming, and piercing in sequence

Cost-effective manufacturing through reduced setup times and automated material handling

Key Features of Progressive Dies

Multi-Station Design

Progressive dies are typically composed of multiple stations arranged sequentially along the path of the metal strip.

Sequential Operations

Each station performs a specific operation, such as cutting, bending, or forming, until the final part is produced.

High Production Rates

Progressive dies are ideal for high-volume production due to their ability to perform multiple operations in a single stroke.

Cost-Effectiveness

By reducing the need for multiple tooling setups, progressive dies can be more cost-effective than other stamping methods.

Automation Integration

Progressive dies are often designed for integration with automated systems, further increasing production speed and efficiency.

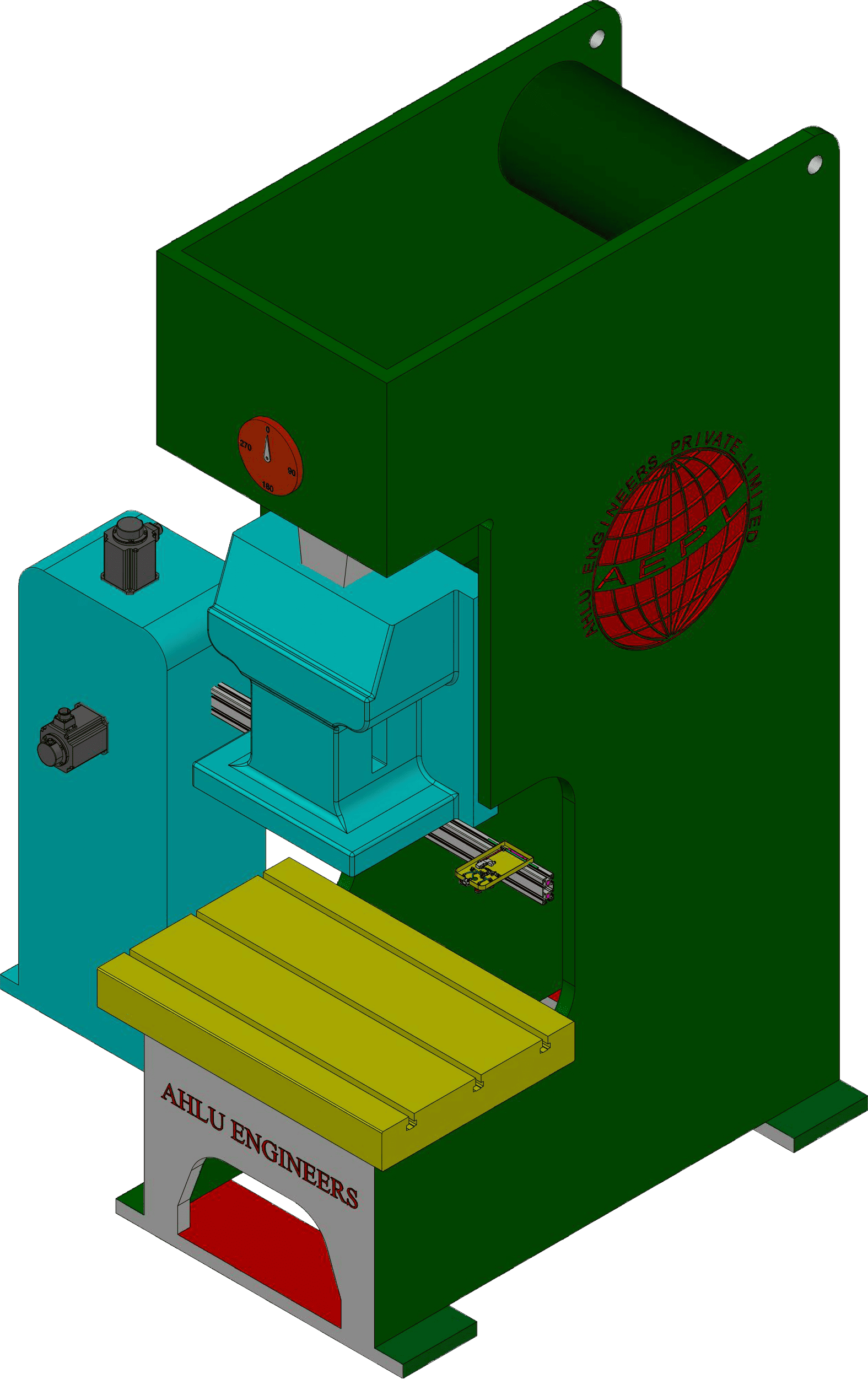

Where Ahlu Engineers Adds Value

At Ahlu Engineers, we specialize in designing and building precision-engineered progressive dies tailored to your application. Our in-house expertise allows us to:

Optimize strip layout and station sequencing for maximum material utilization

Design pilot and carrier systems for precise part progression

Engineer dies for high-speed production with minimal maintenance requirements

Provide comprehensive die validation and production optimization support

Industries We Serve

Automotive

(Chassis, Brackets, Seat Structures)

Electronics

(Terminals, Connectors, EMI Shielding)

Aerospace

(Brackets, Fasteners, Lightweight Components)

Appliances

(Sheet Metal Parts, Enclosures)

Ready to Increase Your Production?

At Ahlu Engineers, we don't just build tools we engineer solutions that transform your manufacturing process into a high-efficiency, cost-effective operation. Contact us today for custom progressive die development, material optimization consultation, or complete tooling design services.

Explore Our Premium Solutions

Our wide array of expertly designed automation solutions, tailored to enhance your manufacturing processes with precision and efficiency.

Ahlu Cantilever Servo Transfer System- ACSTS Series

Ahlu Servo Transfer 2 Axis Double Bar type- AST2AII

Transfer Dies

Ahlu Blank Feeder- ABF Series

Need a Custom Automation Solution?

Our experienced engineers specialize in designing tailored automation systems that perfectly match your unique manufacturing requirements. From concept to implementation, we deliver precision-engineered solutions that boost productivity and efficiency.

✓Expert Engineering Team

45+ years of automation experience

✓Industry Leading Innovation

Cutting Edge automation solutions for modern challenges

✓Complete Support

From design to maintenance & training

Our automation experts are here to help.