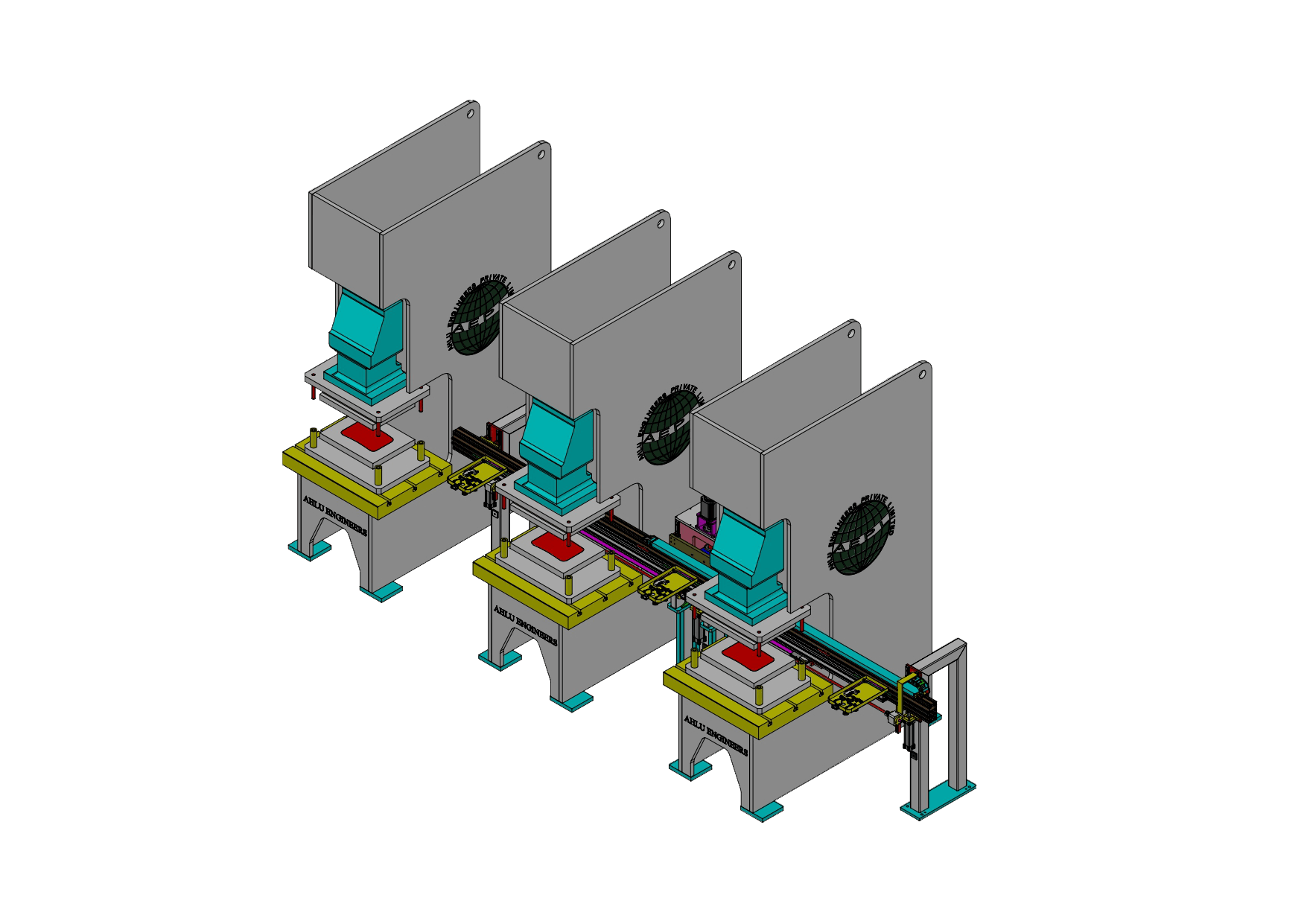

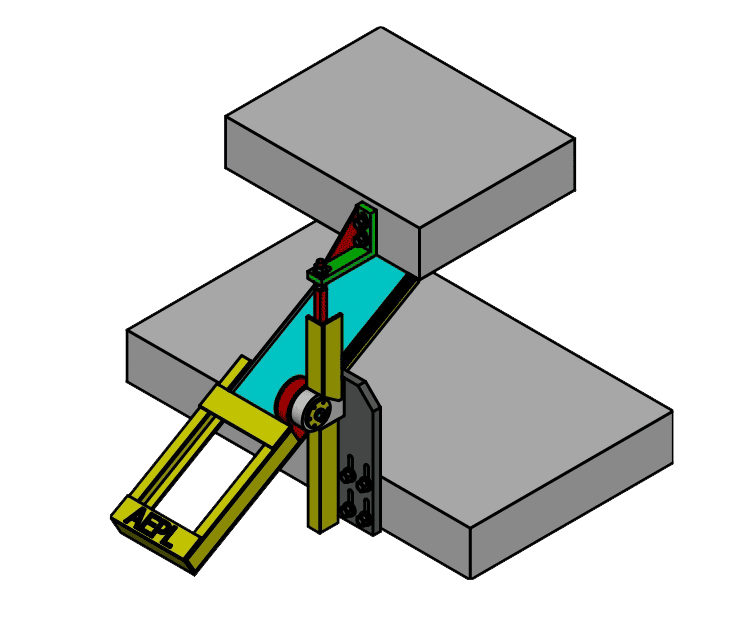

Ahlu Multi Press Transfer System- AMPTS Series

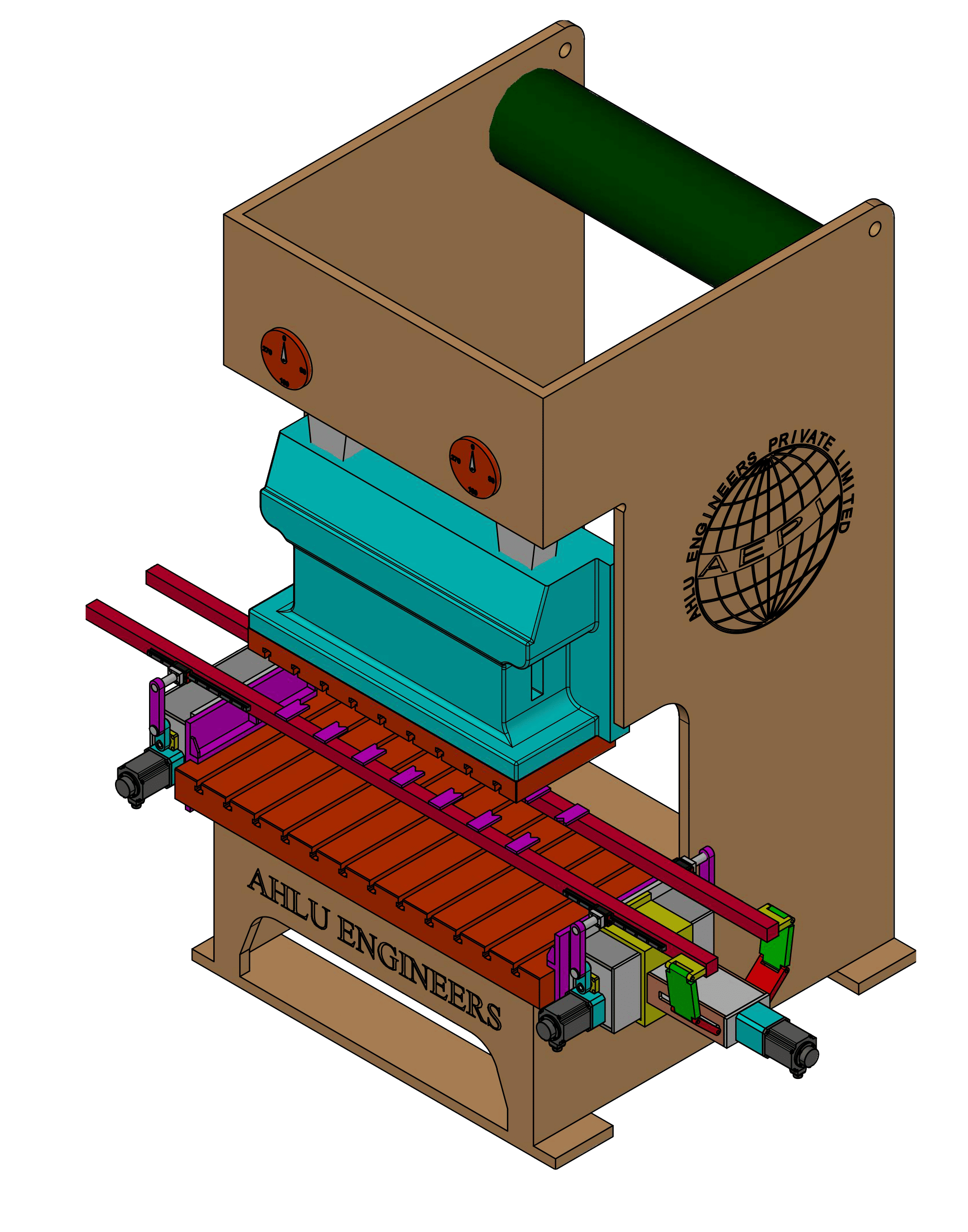

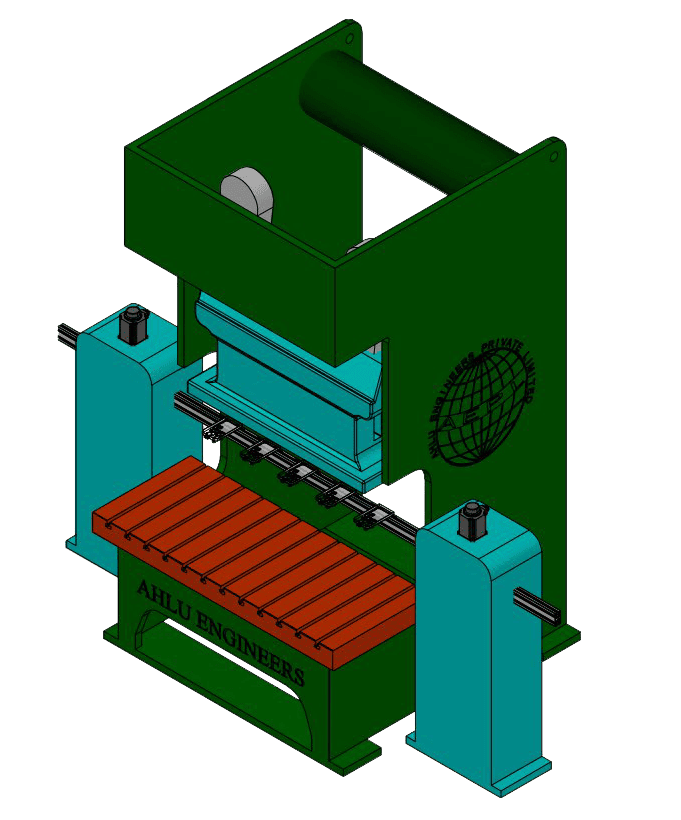

Customized system designed to achieve transfers between individual presses in 2 Axis with additional Gripper axis involved. This Servo programmable transfer system drives a transfer unit with the help of a Single bar mechanism. Three variants of the AMPTS series are available so that you can select a transfer pitch appropriate for your purpose. This system is designed to function in batches of 3 Presses i.e, Multiple of 3 Presses will decide the number of Individual systems required to do the job.

Common Characteristics of Double Bar System

- Each Servo Axis is operated with high accuracy with the help of Precision Servos.

- To Protect Tooling and Machine, each system is by-default comes with mis-feed, die-stuckage & Jamming detection feedbacks are taken in each process cycle to provide required safety.

- The Position Synchronization is performed with the help of Rotary Encoders which connects to the crankshaft of the press. All the transfer axes are driven by servo motor and run synchronously with the press.

- Along with Encoders, Transfer System Controller stays in-continuous communication with press PLC along with the Additional Hard Sensors mounted on output shaft via Rotary cam box to reduce any accidental risk in case of Encoder failure.

- Blank Feeders are generally used to feed Blanks via Magazine type feeders but Servo Sheet Feeders or Zig Zag Feeders can also be utilized by customizing to suit Transfer system & its respective press.

Product Catalogue

Ahlu Multi Press Transfer System- AMPTS Series

Download Product Catalogue

Get comprehensive technical information, specifications, and usage guidelines for Ahlu Multi Press Transfer System- AMPTS Series.

Free download • No spam • Instant access

Product Videos

Explore Our Premium Solutions

Our wide array of expertly designed automation solutions, tailored to enhance your manufacturing processes with precision and efficiency.

Ahlu Servo Transfer 2 Axis Double Bar type- AST2AII

Ahlu Servo Transfer 2 Axis Single Bar type- AST2AI

Compound Dies

Ahlu Mechanical Press Flap Series- AMPF

Need a Custom Automation Solution?

Our experienced engineers specialize in designing tailored automation systems that perfectly match your unique manufacturing requirements. From concept to implementation, we deliver precision-engineered solutions that boost productivity and efficiency.

✓Expert Engineering Team

45+ years of automation experience

✓Industry Leading Innovation

Cutting Edge automation solutions for modern challenges

✓Complete Support

From design to maintenance & training

Our automation experts are here to help.